- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What Makes a Hot Dip Galvanized Structural Brick Machine Curing Kiln Essential for Modern Brick Production?

2025-12-09

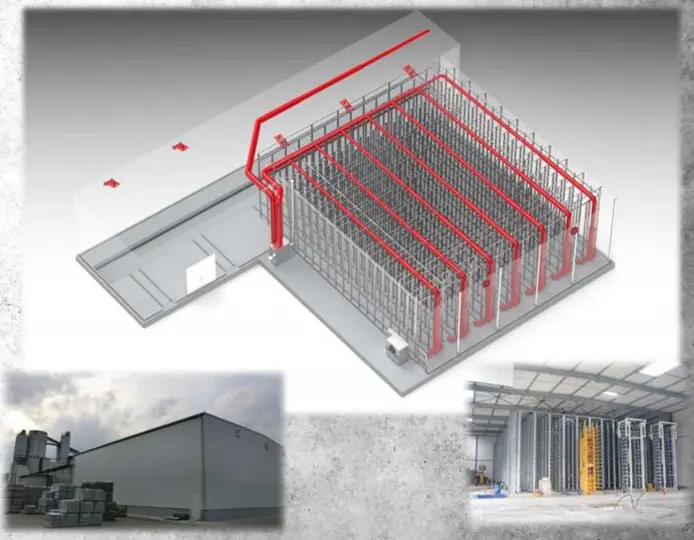

A Hot Dip Galvanized Structural Brick Machine Curing Kiln is a core component in advanced brick manufacturing lines, designed to deliver long-term durability, higher production efficiency, and stable curing environments for high-strength bricks. In today's construction industry—where product consistency, equipment lifespan, and low maintenance costs are crucial—this type of curing kiln offers clear advantages. Its hot-dip-galvanized structural frame ensures exceptional corrosion resistance, especially in humid and high-temperature curing environments, making it suitable for long-term operation in industrial settings.

This article explores how the kiln works, why it has become indispensable, its technical specifications, and how to choose the right model for your production line. A parameter table is also included for clarity and deeper technical understanding.

Why Is a Hot Dip Galvanized Structural Brick Machine Curing Kiln Critical for Stable Brick Strength?

A high-quality curing kiln directly impacts the strength, density, and durability of finished bricks. During the curing stage, moisture and temperature must remain strictly controlled to ensure proper hydration reactions within the material.

A Hot Dip Galvanized Structural Brick Machine Curing Kiln provides:

-

Consistent curing temperature and humidity

Ensures uniform hardening across every batch of bricks. -

Corrosion-resistant structural frame

The hot-dip galvanizing process protects the steel structure from rust and chemical reactions caused by moisture, steam, and curing compounds. -

Extremely long service life

Galvanized surfaces extend the lifespan of the equipment, lowering replacement costs. -

Reduced maintenance requirements

Ideal for manufacturers who demand continuous, high-capacity production.

How Does a Hot Dip Galvanized Structural Brick Machine Curing Kiln Operate Efficiently?

The curing kiln uses controlled steam, heat, and humidity to accelerate the curing process. The reinforced galvanized frame supports insulated chambers that maintain stable environmental conditions.

Key operational advantages include:

-

Automated control system for temperature, humidity, and curing cycles

-

Uniform heat distribution to ensure consistent brick quality

-

High-strength galvanized structure that withstands long-term thermal expansion

-

Energy-efficient design to reduce operational costs

-

Modular construction for easy installation and future expansion

The kiln integrates seamlessly with brick production equipment such as block machines, batching systems, and palletizing units.

What Technical Parameters Should You Consider When Selecting a Hot Dip Galvanized Structural Brick Machine Curing Kiln?

Below is a simplified parameter table for standard kiln configurations used in industrial brick manufacturing lines:

Technical Specifications Table

| Parameter Category | Specification Details |

|---|---|

| Structure Material | Hot Dip Galvanized High-Strength Steel |

| Corrosion Resistance | ≥ 20 years anti-corrosion lifespan |

| Temperature Control Range | 30°C – 75°C adjustable |

| Humidity Control Range | 60% – 98% RH adjustable |

| Insulation Thickness | 50–100 mm high-density insulation |

| Curing Chamber Size | Customizable from 30 m³ to 300 m³ |

| Control System | PLC automatic management with touch-screen interface |

| Energy Source | Steam, electric, or biomass options |

| Operational Efficiency | 15–30% lower energy consumption compared to traditional kilns |

| Design Type | Modular chambers for flexible layout |

| Maintenance Requirement | Low—surface requires no regular repainting |

| Expected Lifespan | 25–35 years depending on environment |

These parameters may vary based on project scale, production volume, or customized configurations.

Which Advantages Does a Hot Dip Galvanized Structural Brick Machine Curing Kiln Offer Compared to Traditional Kilns?

1. Corrosion Resistance

Traditional painted steel structures deteriorate quickly in high-humidity environments. Hot-dip galvanized structures resist corrosion significantly longer.

2. Extended Lifespan

The zinc coating provides long-term protection, greatly reducing structural degradation.

3. Improved Brick Quality

Stable curing conditions guarantee consistent compressive strength and surface durability.

4. Reduced Maintenance Cost

No frequent repainting or structural patching is required.

5. Energy Efficiency

The kiln uses optimized insulation and automated controls to reduce heat loss.

6. Better Environmental Adaptability

Suitable for regions with harsh climates or corrosive industrial environments.

How to Ensure Optimal Performance When Using a Hot Dip Galvanized Structural Brick Machine Curing Kiln?

To achieve the best operating results:

-

Maintain clean airflow and ventilation channels inside the kiln.

-

Regularly inspect insulation to prevent thermal leakage.

-

Calibrate sensors periodically for accurate temperature and humidity readings.

-

Follow recommended curing cycles for specific brick types.

-

Train operators to use PLC controls properly for efficient management.

Proper operation maximizes energy savings and extends equipment lifespan.

FAQ About Hot Dip Galvanized Structural Brick Machine Curing Kiln

Q1: What makes a Hot Dip Galvanized Structural Brick Machine Curing Kiln more durable than standard steel kilns?

A1: The hot-dip galvanizing process coats the steel with a thick zinc layer that prevents rust, corrosion, and moisture damage. This protection significantly increases the kiln's service life, especially under long-term high-humidity curing conditions.

Q2: How does this curing kiln improve the quality of bricks?

A2: The kiln maintains precise temperature and humidity, ensuring uniform curing. This leads to consistent strength, reduced cracking, and improved density of finished bricks.

Q3: Is a Hot Dip Galvanized Structural Brick Machine Curing Kiln suitable for large-scale production lines?

A3: Yes. Its modular design, automated control system, and durable structure support continuous, high-volume brick manufacturing with minimal downtime.

Q4: Can the curing kiln be customized for different production requirements?

A4: Absolutely. Chamber size, energy source, insulation thickness, and control systems can be fully tailored to match production capacity and environmental conditions.

Why Choose a Hot Dip Galvanized Structural Brick Machine Curing Kiln?

This curing kiln represents a modern, durable, and energy-efficient solution for industrial brick manufacturing. Its advanced corrosion-resistant structure, stable curing performance, and long-term operational reliability set it apart from traditional options. Manufacturers investing in this type of curing kiln benefit from higher product quality, reduced maintenance costs, and long-lasting equipment stability.

For detailed specifications, quotations, and customized solutions, please feel free to contact QUANGONG MACHINERY CO., LTD. We provide comprehensive support for brick production lines and offer professional engineering guidance for your project needs.

Next :

-

Related News

- Why Choose a Brick Machine With Frame Curing Kiln for Modern Construction?

- Why Is a Brick-Concrete Structure Curing Kiln Essential for Modern Construction Projects?

- What Is a Brick Machine Temperature Control System and Why Is It Important?

- Why Choose a Brick Machine With Frame Curing Kiln for Modern Construction Efficiency?

- What Exactly is a Concrete Brick Machine Curing Kiln?

- Why Is a Brick-Concrete Structure Curing Kiln Essential for Modern Construction?

New Products