- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How Does a Block Making Machine Curing Kiln Improve Concrete Block Quality and Production Efficiency?

A Block Making Machine Curing Kiln plays a critical role in modern concrete block production by providing a controlled environment for curing freshly formed blocks. Without proper curing, even the most advanced block making machines cannot achieve consistent strength, durability, or surface quality. This article explores how curing kilns work, why they matter, and how manufacturers can choose the right solution to improve productivity and long-term profitability.

Article Abstract

This comprehensive guide explains the concept, structure, and performance advantages of a Block Making Machine Curing Kiln. It covers working principles, core components, benefits compared to traditional curing methods, selection criteria, and real-world applications. The article also answers frequently asked questions and provides industry references, making it a valuable resource for block manufacturers seeking reliable curing solutions from experienced suppliers such as QUANGONG MACHINERY CO.,LTD.

Table of Contents

- What Is a Block Making Machine Curing Kiln?

- How Does a Block Making Machine Curing Kiln Work?

- Why Is a Curing Kiln Essential for Concrete Block Production?

- Which Types of Curing Kilns Are Used in Block Making Plants?

- How Does a Curing Kiln Improve Block Quality and Strength?

- What Are the Key Technical Parameters of a Curing Kiln?

- How to Choose the Right Curing Kiln for Your Block Making Machine?

- Why Work with QUANGONG MACHINERY CO.,LTD?

- Frequently Asked Questions

- References

What Is a Block Making Machine Curing Kiln?

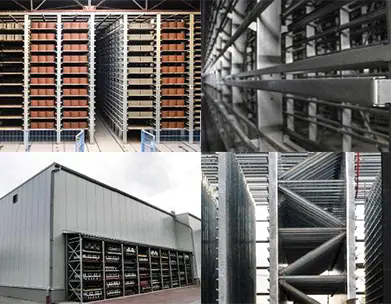

A Block Making Machine Curing Kiln is a specialized curing system designed to maintain optimal temperature and humidity conditions for concrete blocks after molding. Its main purpose is to accelerate cement hydration while ensuring uniform strength development across all blocks.

Unlike open-air curing, a curing kiln provides precise environmental control, reducing cracking, deformation, and inconsistent strength. This makes it an indispensable component in automated and semi-automated block production lines.

How Does a Block Making Machine Curing Kiln Work?

The curing process begins immediately after blocks exit the block making machine. Fresh blocks are transferred into the curing kiln using racks, pallets, or automated handling systems. Inside the kiln, temperature and humidity are regulated through steam injection, hot air circulation, or combined systems.

- Temperature is typically maintained between 40°C and 80°C.

- Relative humidity is kept above 90% to prevent moisture loss.

- Automated controls ensure consistent curing cycles.

By controlling these variables, the curing kiln enables faster strength gain while preserving structural integrity.

Why Is a Curing Kiln Essential for Concrete Block Production?

Proper curing directly affects the mechanical properties of concrete blocks. A Block Making Machine Curing Kiln ensures that hydration occurs evenly, reducing internal stresses and surface defects.

Key reasons curing kilns are essential include:

- Shortened production cycles

- Higher early and final compressive strength

- Reduced dependency on weather conditions

- Lower rejection rates and material waste

For large-scale manufacturers, these benefits translate into predictable output and improved return on investment.

Which Types of Curing Kilns Are Used in Block Making Plants?

Several types of curing kilns are commonly used depending on production scale and climate conditions:

| Curing Kiln Type | Main Features | Best Application |

|---|---|---|

| Steam Curing Kiln | High humidity, fast strength gain | High-volume industrial production |

| Hot Air Curing Kiln | Stable temperature control | Moderate production lines |

| Natural Curing Chamber | Low energy consumption | Small-scale or warm climates |

How Does a Curing Kiln Improve Block Quality and Strength?

The controlled environment inside a Block Making Machine Curing Kiln prevents premature drying, which is one of the main causes of weak concrete. By maintaining ideal curing conditions, blocks achieve:

- Higher compressive strength

- Better dimensional stability

- Improved surface appearance

- Longer service life

Manufacturers working with QUANGONG MACHINERY CO.,LTD often report significant reductions in quality-related complaints after upgrading to advanced curing kiln systems.

What Are the Key Technical Parameters of a Curing Kiln?

When evaluating a curing kiln, several technical parameters should be considered:

- Chamber dimensions and capacity

- Temperature and humidity control range

- Energy consumption

- Automation and monitoring system

- Compatibility with existing block making machines

Advanced systems from QUANGONG MACHINERY CO.,LTD are designed to integrate seamlessly with fully automated block production lines.

How to Choose the Right Curing Kiln for Your Block Making Machine?

Selecting the right Block Making Machine Curing Kiln depends on production goals, budget, and local climate. Decision-makers should assess daily output requirements, available space, and energy costs.

It is also recommended to consult experienced manufacturers. You can explore professional curing solutions through block production system experts to ensure long-term reliability.

Why Work with QUANGONG MACHINERY CO.,LTD?

QUANGONG MACHINERY CO.,LTD is a globally recognized supplier of block making machines and curing kiln systems. With decades of engineering experience, the company provides customized curing solutions tailored to different production scales and regional requirements.

Their curing kiln systems emphasize durability, energy efficiency, and intelligent control, helping manufacturers stay competitive in demanding construction markets.

Frequently Asked Questions

Q: What is the main function of a Block Making Machine Curing Kiln?

A: Its main function is to provide a controlled temperature and humidity environment that allows concrete blocks to gain strength evenly and efficiently after molding.

Q: How long do blocks need to stay inside a curing kiln?

A: Depending on the mix design and curing method, blocks typically remain in the kiln for 8 to 24 hours to achieve sufficient early strength.

Q: Can a curing kiln work in cold climates?

A: Yes, curing kilns are especially beneficial in cold climates because they eliminate the negative impact of low temperatures on cement hydration.

Q: Is a curing kiln suitable for fully automatic block making machines?

A: Absolutely. Modern curing kilns are designed to integrate with automated handling systems and centralized control platforms.

Q: Why choose QUANGONG MACHINERY CO.,LTD for curing kiln solutions?

A: QUANGONG MACHINERY CO.,LTD offers proven technology, global service support, and customized designs that align with diverse production needs.

References

- ACI Committee 308 – Guide to External Curing of Concrete

- PCI Manual for Quality Control for Plants and Production of Structural Concrete Products

- Concrete Technology by A.M. Neville

If you are looking to upgrade your block production line with a reliable and efficient curing solution, contact us today. The expert team at QUANGONG MACHINERY CO.,LTD is ready to help you design the ideal Block Making Machine Curing Kiln system tailored to your business goals.

Next :

-

Related News

- Why Choose a Block Making Machine Curing Kiln for Efficient Block Production?

- What Makes a Hot Dip Galvanized Structural Brick Machine Curing Kiln Essential for Modern Brick Production?

- Why Choose a Brick Machine With Frame Curing Kiln for Modern Construction?

- Why Is a Brick-Concrete Structure Curing Kiln Essential for Modern Construction Projects?

- What Is a Brick Machine Temperature Control System and Why Is It Important?

- Why Choose a Brick Machine With Frame Curing Kiln for Modern Construction Efficiency?

Leave me a message