- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What are the ways to use the Fully Automatic Cement Brick Machine Maintenance System?

One of the key ways to utilize the Fully Automatic Cement Brick Machine Maintenance System is through its predictive maintenance capabilities. By leveraging advanced sensors and data analytics, the system can detect potential issues before they escalate into major problems, allowing for proactive maintenance and minimizing downtime. This predictive approach not only extends the lifespan of the machinery but also reduces maintenance costs in the long run.

Furthermore, the Fully Automatic Cement Brick Machine Maintenance System offers remote monitoring features that enable operators to keep a close eye on the machine's performance from anywhere at any time. Whether it's monitoring production output, tracking energy consumption, or analyzing maintenance data, the system provides real-time insights that empower decision-makers to make informed choices and optimize operational efficiency.

In addition to predictive maintenance and remote monitoring, another valuable application of the Fully Automatic Cement Brick Machine Maintenance System is its ability to automate routine maintenance tasks. By scheduling maintenance activities based on machine usage and performance metrics, operators can ensure that the equipment is always operating at peak efficiency without the need for manual intervention. This automation not only saves time and labor costs but also reduces the risk of human errors that could lead to equipment malfunction.

Related News

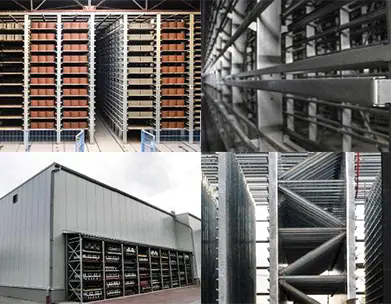

- Why Choose a Block Making Machine Curing Kiln for Efficient Block Production?

- What Makes a Hot Dip Galvanized Structural Brick Machine Curing Kiln Essential for Modern Brick Production?

- Why Choose a Brick Machine With Frame Curing Kiln for Modern Construction?

- Why Is a Brick-Concrete Structure Curing Kiln Essential for Modern Construction Projects?

- What Is a Brick Machine Temperature Control System and Why Is It Important?

- Why Choose a Brick Machine With Frame Curing Kiln for Modern Construction Efficiency?

Leave me a message

New Products