- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Curing Kiln: The Precision Heat Treatment Solution for Industrial Applications

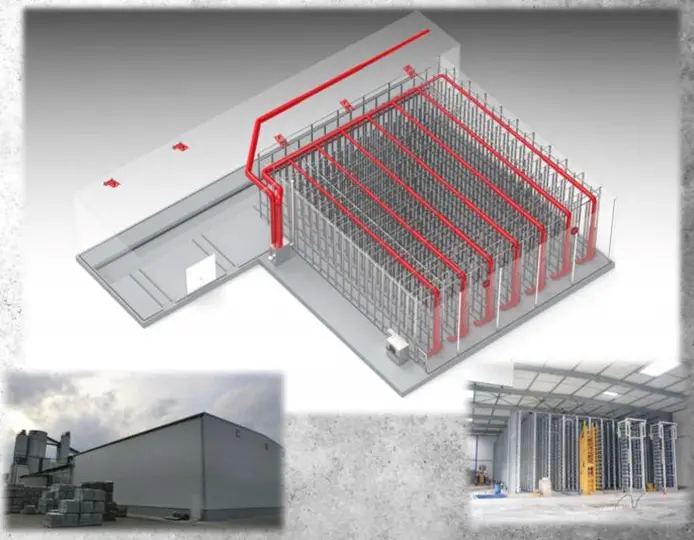

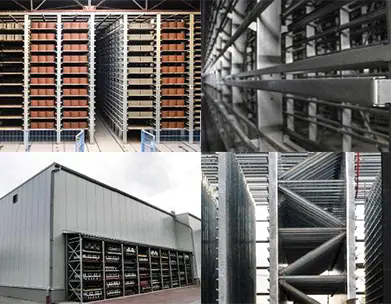

A curing kiln is an advanced thermal processing system designed to harden, dry, or chemically transform materials under controlled conditions. Unlike standard industrial ovens, curing kilns provide precise temperature and environmental control, ensuring consistent quality in manufacturing processes.

Why Use a Curing Kiln?

- Uniform Heating – Eliminates hot/cold spots for even curing

- Programmable Cycles – Custom ramp-up, hold, and cooling phases

- Material-Specific Optimization – Tailored for composites, ceramics, coatings, and more

- Repeatable Results – Critical for aerospace, automotive, and medical industries

Key Applications

✔ Composite Manufacturing – Curing carbon fiber/epoxy parts

✔ Ceramics & Pottery – Firing clay and glazes

✔ Powder Coating – Bonding coatings to metal surfaces

✔ Electronic Encapsulation – Setting adhesives and potting compounds

✔ Rubber & Silicone Vulcanization – Strengthening elastomers

Types of Curing Kilns

1. Batch Kilns – Manual loading for small to medium production

2. Continuous Kilns – Conveyor-fed for high-volume manufacturing

3. Vacuum Kilns – For oxygen-sensitive materials

4. Infrared Kilns – Fast, energy-efficient curing

Critical Features to Consider

- Temperature Range (100°C to 1,000°C+)

- Heating Method (electric, gas, infrared)

- Atmosphere Control (air, nitrogen, inert gas)

- Data Logging & Automation (for quality assurance)

Best Practices for Optimal Curing

- Precise Ramp Rates – Avoid thermal shock

- Proper Ventilation – Prevent off-gassing buildup

- Regular Calibration – Ensure temperature accuracy

Whether producing high-performance composites or durable ceramic components, a curing kiln ensures materials achieve their maximum strength and performance. Investing in the right system means fewer defects, higher efficiency, and superior end products.

Need a curing solution? Match your material requirements with the right kiln specifications for flawless results every time.

Founded in 1979, Quangong Machinery Co., Ltd. (QGM) is headquartered in Quanzhou, Fujian, covering an area of 60 acres and has a registered capital of 100 million yuan. It is a high-tech enterprise specializing in the research and development, manufacturing and sales of ecological concrete block making equipment.The company's products cover a full range of ecological concrete block machine, and provide management consulting services, technology upgrading, talent training and production trusteeship services for the industry. Visit our website at https://www.qgmbrickcuringkiln.com/ to learn more about our products. For inquiries, you can reach us at zoul@qzmachine.com.

Related News

- Why Choose a Block Making Machine Curing Kiln for Efficient Block Production?

- What Makes a Hot Dip Galvanized Structural Brick Machine Curing Kiln Essential for Modern Brick Production?

- Why Choose a Brick Machine With Frame Curing Kiln for Modern Construction?

- Why Is a Brick-Concrete Structure Curing Kiln Essential for Modern Construction Projects?

- What Is a Brick Machine Temperature Control System and Why Is It Important?

- Why Choose a Brick Machine With Frame Curing Kiln for Modern Construction Efficiency?

Leave me a message

New Products