- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Hot Dip Galvanized Structural Brick Machine Curing Kiln: A Critical Component in the Galvanizing Industry

The hot dip galvanized structural brick machine curing kiln is a critical component in the galvanizing industry, playing a vital role in ensuring the quality and durability of galvanized structural bricks. These bricks are essential in construction and infrastructure projects, providing corrosion resistance and structural integrity to buildings and other structures.

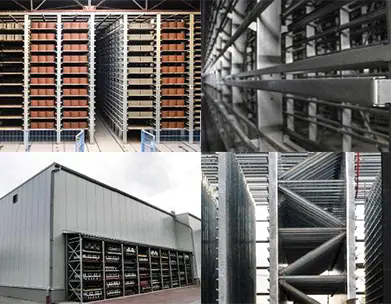

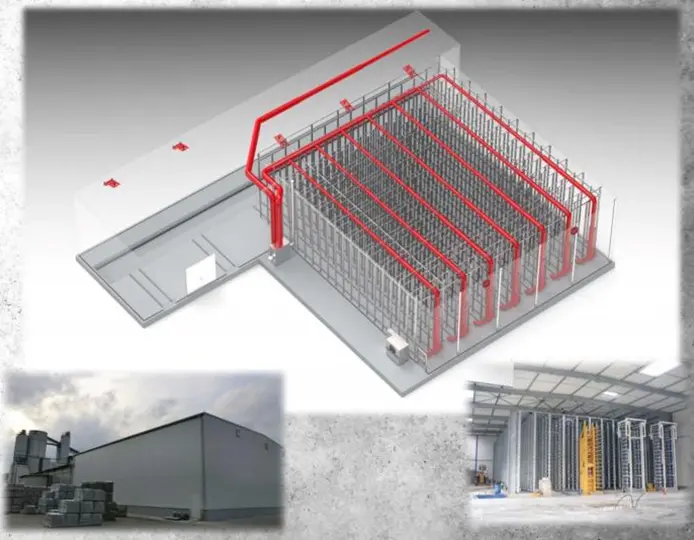

The galvanizing process involves coating iron or steel with a protective layer of zinc to prevent corrosion. Structural bricks, which are primarily used in load-bearing walls and foundations, require a high-quality galvanizing process to ensure they can withstand environmental conditions over long periods. The curing kiln is a specialized piece of equipment designed to heat and cool the galvanized structural bricks at controlled temperatures, allowing the zinc to bond properly and form a protective layer.

In recent years, the demand for hot dip galvanized structural brick machine curing kilns has increased due to growing construction activities and the need for durable and long-lasting construction materials. The curing kiln is a key factor in achieving the desired galvanizing quality, as it ensures that the zinc layer adheres uniformly and completely to the structural bricks.

The market for hot dip galvanized structural brick machine curing kilns is segmented into various types based on capacity, temperature control systems, and energy efficiency. High-capacity curing kilns are preferred for large-scale production, while smaller models are suitable for smaller operations. Advanced temperature control systems ensure precise heating and cooling, which is crucial for achieving consistent and high-quality galvanizing results. Energy-efficient designs help reduce operational costs and minimize environmental impact.

Manufacturers in the curing kiln industry are focusing on improving product performance and sustainability. Key trends include the development of more efficient heating systems, advanced insulation materials, and more automated control systems. These advancements not only enhance the quality of galvanized structural bricks but also contribute to energy savings and reduced carbon footprints.

The global market for hot dip galvanized structural brick machine curing kilns is expected to grow in the coming years, driven by factors such as urbanization, infrastructure development, and the increasing demand for corrosion-resistant construction materials. However, the industry faces challenges such as stringent environmental regulations, competition from alternative materials, and the need for continuous innovation.

In conclusion, the hot dip galvanized structural brick machine curing kiln is a critical component in the galvanizing industry, essential for ensuring the quality and durability of galvanized structural bricks. As the industry continues to evolve, manufacturers are focusing on enhancing product performance and sustainability to meet the growing demands of the construction sector. The future of this industry is promising, with ongoing technological advancements and expanding market opportunities.

Related News

- Why Choose a Block Making Machine Curing Kiln for Efficient Block Production?

- What Makes a Hot Dip Galvanized Structural Brick Machine Curing Kiln Essential for Modern Brick Production?

- Why Choose a Brick Machine With Frame Curing Kiln for Modern Construction?

- Why Is a Brick-Concrete Structure Curing Kiln Essential for Modern Construction Projects?

- What Is a Brick Machine Temperature Control System and Why Is It Important?

- Why Choose a Brick Machine With Frame Curing Kiln for Modern Construction Efficiency?

Leave me a message